Mass flow measurement in a lime plant with MaxxFlow HTC

Application

A producer of lime manufactures a wide range of products in his cement and lime plant. Among others, he produces coarse limestone grains, lime sand, very finely ground unburnt limes or highly reactive lime hydrates.

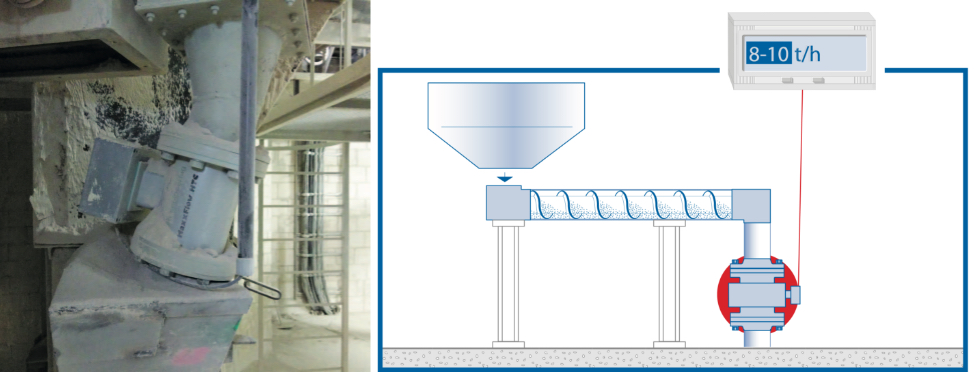

Our customer needed the possibility to measure the quantity of the different lime products during the fabrication processes, to get a more detailed overview of the fabricated material volumes. In the described application the lime, which is delivered to the limestone grinding plant, is ground in the ball mill to fine lime. The final product is carried out of the mill and transported via different screw conveyors and a bucket elevator to a silo. Between the last screw conveyor and the bucket elevator, the material quantity is measured in freefall.

Process data

- Customer: Cement and lime plant Otterbein (Germany)

- Product: Fine lime

- Quantity: 8 – 10 t/h

- Installation place: Freefall between the conveyor belt and bucket elevator

- Function: Quantity measurement of lime meal after the grinding process in a ball mill

Solution

The MaxxFlow HTC measures high mass flow rates from the exit of pre-feeding devices e. g. screw conveyors, air slides, rotary valves or bucket elevators. In addition to low height, characteristics like maintenance and wear-free measurement and an easy calibration make the MaxxFlow HTC an effective mass flow measurement device for large volumes of bulk materials. Our customer uses the MaxxFlow HTC in his lime plant at different places. It provides the capture of material quantities, which enables the accounting of the processed material.

Customer benefit

- wear-free in comparison with other systems

- low installation height

- no flow restrictions to the process flow

- simple calibration

- simple detection of material quantities

- installation in an inclined line is possible, therefore minimization of installation costs